OUR LONG EXPERIENCE AT AN INTERNATIONAL LEVEL COMBINED WITH OUR FLEXIBILITY MAKES A.E.I. A RELIABLE PARTNER ABLE TO MANAGE BOTH SIGNIFICANT ORDERS AND SMALL JOBS.

The management of a project is critical to its success! Customers’ requests, functional specifications and manufacturing characteristics are analysed in great detail.

Every production stage is planned and monitored continually.

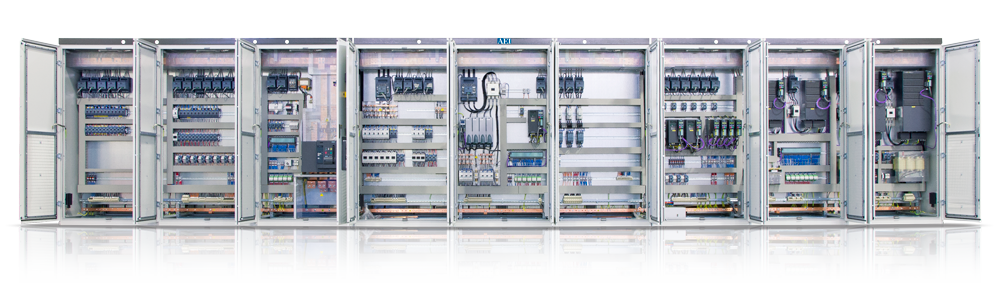

A feature of A.E.I. systems is their ease of maintenance and of future implementations and/or modifications.

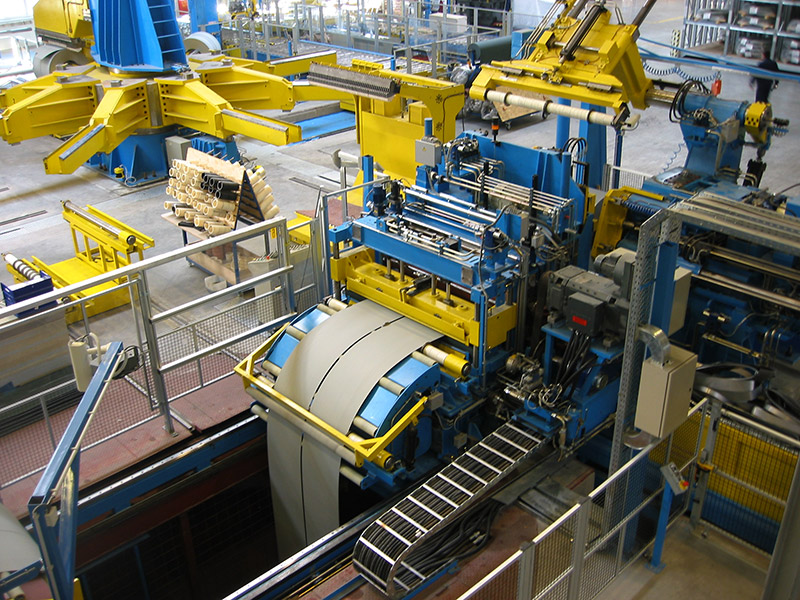

The work of A.E.I. can be simplified into three broad categories:

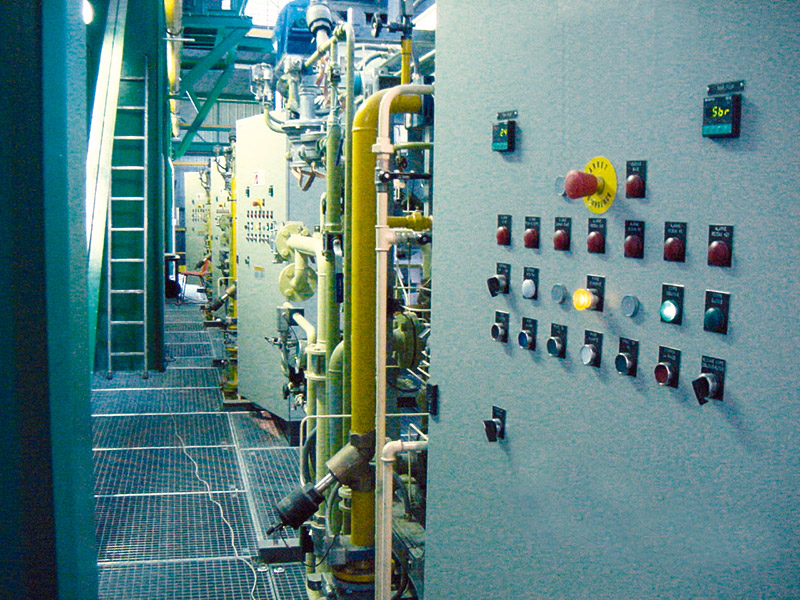

- Creation of automation equipment for new machines/systems

- Creation of automation equipment for updating and modernizing existing machines/systems (revamping)

- Modification and adaptation of existing equipment